Keli Motor Group Search

Servo Motors Product Solutions

Summary:The 6-axis multi-articulated robot also known as articulated arm robots or articulated robotic arms, are one of the most common forms of industrial robots in industry today and are suitable

1. multi-articulated robot solutions

The 6-axis multi-articulated robot also known as articulated arm robots or articulated robotic arms, are one of the most common forms of industrial robots in industry today and are suitable for mechanical automation in many industrial fields. Each robot body uses 6 servo motors, which can be divided into various models according to the arm length and load gripping weight of the robot, and the servo motors used range from tens of watts to several kilowatts.

Application areas: Industrial robots

Description: The six-axis multi-articulated robot requires high torque, high speed, small size, low torque fluctuation, high response speed, reliability for long uninterrupted operation, and a comprehensive product range. The rotors of our KS series (some models) servo motor have a magnetic ring structure, which can achieve high speed and small size without reducing the torque and at the same time have a very good torque fluctuation characteristics. Our products cover motor capacities from 50W to 4.4kW and can be used for most robotic machines.

Advantage of the solution: With a comprehensive product range, customers can make a one-stop purchase, providing higher torque and speed characteristics with high reliability, improving the robot's operating efficiency and ensuring smooth operation with low torque fluctuations.

2. SCARA Robot Solutions

SCARA robot also known as horizontal multi-articulated robot, is a cylindrical coordinate type of special type of industrial robots, mostly used in high-speed assembly, handling, grinding, packaging and other industries. The robot has high requirements for running beat time, requiring high speed, high responsiveness and high overload capacity.

Application areas: Industrial robots

Description: We have a choice of small-capacity motors with a maximum speed of 6,000 rpm, which enables high-speed operation and shortens the beat time. It can also be combined with an optical 23-bit multi-turn absolute encoder to achieve high positioning accuracy. The excellent overload resistance of the motor also makes it possible to operate the equipment continuously under high loads.

Advantage of the solution: High speed and high responsiveness shorten the equipment beat time, high overload capacity ensures stable operation of the equipment.

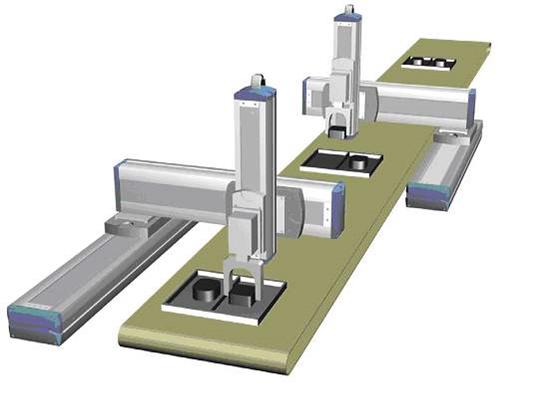

3. Manipulator Solutions:

Robots also known as right-angle coordinate robots are generally used for material picking, handling, sorting, etc. According to the industry can be divided into injection molding robot, machine tool robot, die-casting robot, stamping robot, etc. Servo motor performance and price have higher requirements due to fierce competition in the industry.

Application areas: Manipulator

Description: Our KJ series servo motors are designed with a balance of performance and cost in mind and are available in relatively low cost magnetic tile motors, optical incremental or magnetic encoders but at the same time, In order to ensure the basic performance of the motor without abandoning the industry's high-performance servo motor only 5 to 10-pole structure. Achieves a balance of performance and cost.

Advantage of the solution: For specific industries, it offers a better price&performance ratio while meeting performance.

4. Automatic locking screw machine solutions.

The three-axis locking screw machine with a wide range of working surface, high degree of freedom and flexibility, fast running speed can be hand-dragged Z-axis for fast positioning of screw points, in small space or large products and other aspects of the problem is well solved. As with many non-standard automation equipment, the motor needs to be customized according to the characteristics of the equipment in order to meet the needs of the equipment, to improve the productivity of the equipment, to achieve the perfect match between the motor and the equipment, etc. The customer found the motor comes with short cable during produce process, it needs to be extended, but the docking plug between the extension cable and the motor cable is inside the equipment, when the equipment is running the adapter becomes vulnerable to bad contact instability and at the same time there is some inconvenience during production.

Application areas: Automation equipment

Description:In order to facilitate the assembly of the equipment and reduce the number of intermediate adapter plugs to increase the stability of the equipment, the customer requested a custom motor cable and plug. Our servo motors provide customized cables and plugs as well as plug pin definitions to match the customer's drives to meet the needs of the equipment.

Advantage of the solution: We have the flexibility to customize motors to meet the specific needs of our customers and solve their problem.

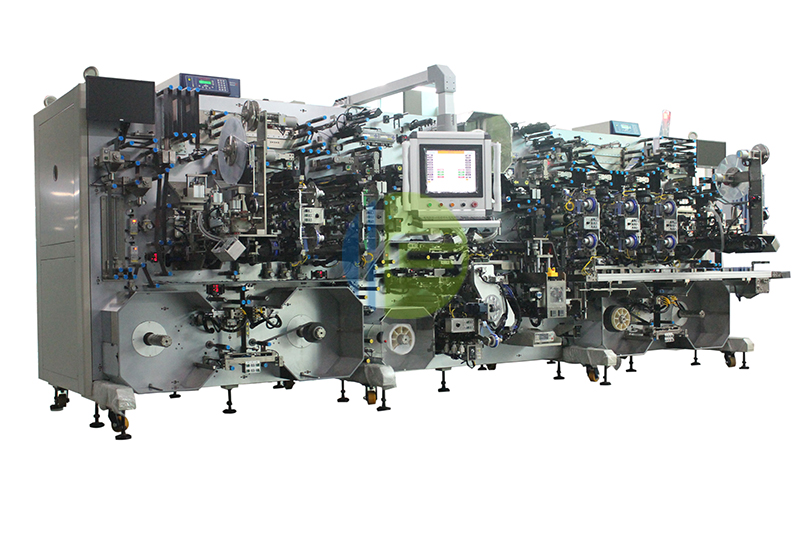

4. Lithium battery production equipment (cell winding machine) machine solutions:

The equipment is used for the fabrication of square lithium-ion battery cells. Through automatic unwind, automatic deviation Correction, tension control, plate lugs folding detection, winding, Paste termination glue, CCD misalignment detection, short-circuit detection, unloading to the conveyor belt and other actions, complete the production of electric core. Due to the need for automatic unwind and high precision tension control during the production process, the stability of the motor's torque output and torque fluctuations are very demanding.

Application areas: Automation equipment

Description:Our 130 and 180 flange series motors also adopt the 10-pole 12-slot structure with small capacity servo below 80 flanges, Although the cost of the product is higher, this structure motor has better real-time response, which can match the fast acceleration and deceleration and tension adjustment action of the equipment. At the same time, the low torque fluctuation characteristics of the structure also ensure the stability of the motor's torque output during operation.

Advantage of the solution: The motor is quick to respond and has low torque fluctuations.